-

Give us a call

+86 17721551076 -

Email us

pressbraketooling@hotmail.com

Most bending parts are produced using air bending, bottom bending, or folding and hemming. These methods and processes all work in the same way: a punch presses the workpiece into the lower tool of the die. That is why the bending machines which carry out these methods and processes are called press brakes.

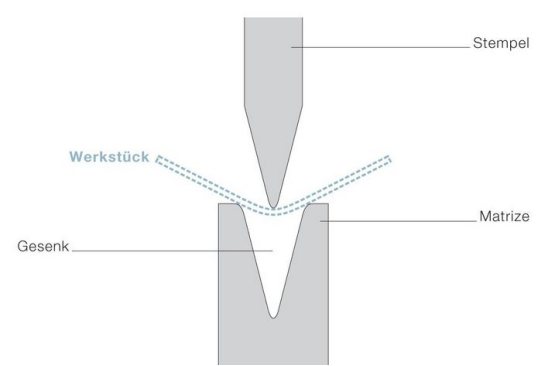

Air bending

With air bending, the punch presses the workpiece into the die without pressing it against the walls. Whilst the punch moves down, the sides of the workpiece bend up, which creates the angle. The deeper the punch presses the workpiece into the die, the more acute the angle. A clearance remains between the punch and the die. Air bending is referred to as a path-dependent method, as each angle requires a defined path. The machine control calculates this path as well as the appropriate press force. The path and press force depend on the tools as well as the material and product properties (angle, length).

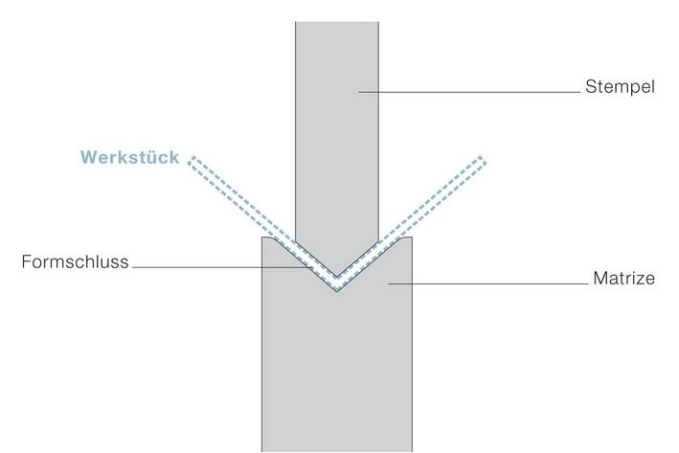

Bottom bending

In bottom bending, the press brake punch presses the workpiece into the die completely so that there is no clearance between the die, workpiece and punch. This is called a form lock. The punch and die must fit into each other exactly. For this reason, a separate tool set is required for each angle and each form. When the workpiece has been completely pressed in, the punch cannot move further down. However, the machine control increases the press force until the predefined value has been reached. This increases the pressure on the workpiece, which then takes on the shape of the punch and the die. The angle stabilises under the high pressure so that spring back is almost completely eliminated.

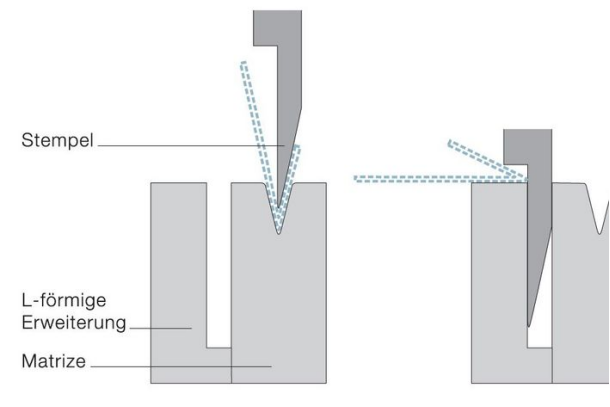

Folding and hemming

Sheet edges are often bent over completely, such as the edges of boxes. The sides are then parallel to each other. This either makes the finished part more stable or creates edge protection. Furthermore, folds are often needed so that another part can be hooked into them at a later stage. Folding and hemming occurs in two steps. In the first step, the operator pre-bends an angle of 30°. Then they reinsert the workpiece and press the angle shut. The procedure is called folding if a gap remains between the sides. With hemming, the sides are pressed completely together. Folding is path-dependent, but hemming is force-dependent.