-

Give us a call

+86 17721551076 -

Email us

pressbraketooling@hotmail.com

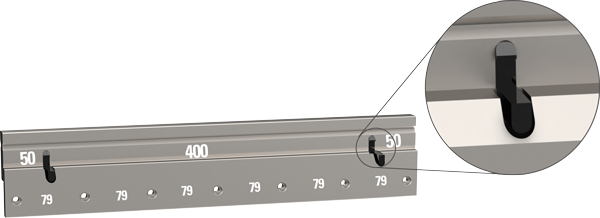

The holders for blades size is 100*28*500mm, the material is 42CrMo4, the weight is 6.7kg.

Product Origin :

MaanshanBrand :

JaminnarOrder(MOQ) :

1Payment :

T/T, Western Union, Alipay, WeChat etc.Shipping Port :

Shanghai / Guangzhou or OtherLead Time :

15 - 20 days after receiving the depositHeat Treatment :

Full body heat treatment / Laser hardeningSurface Color & Surface Treatment :

Silver / Black / Sandblasting|

Tooling system |

JM - System Trumpf/ Wila/ LVD |

|

Angle |

28° |

|

Radius |

0.5mm - 6mm |

|

Total Height |

200 mm |

|

Load |

1000 kN/m max. |

|

Material |

42CrMo |

|

Length and weight |

500mm/6.7kg |

Jaminnar is in the field of sheet metal processing, and is engaged in the production and sale of bending tools and crowning tables. Jaminnar can supply punches and dies for any type of press brake. These tools are made of hardened and ground high quality steels C45 and 42CrMo. Our product range includes tool types such as: Amada / promecam european, Trumpf / Wila, Bystronic/Beyeler, LVD type, EHT type, American type, Gasparini Type, Colgar Type,Colly Type,Ajial-Axial Type, Hämmerle-bystronic Type, Special tools, Shear blades, Crowning Table, Rolla-V, Adjustable Die, Custom Rotary Dies, Clamping system, Tools Storage Cabinets, Protective Traceless Film, etc.

Jaminnar has two in-house R&D department specializing in designing technologically advanced solutions and focuses on innovative solutions, with the support of our technical department we are able to design and supply special punches and dies and research the right solution for your bending project. The tools - our company supplies for press brakes are efficient and durable, thanks to the ability to use cutting-edge technology and uses advanced equipment for production with Implement strict quality control and the guarantee of highly qualified employees. Our molds undergo rigorous testing to ensure stability and durability; Reliability and competitive pricing are two other distinguishing features of our bending tools.

Product advantages

✔ Cost-saving: One holder for different blades

✔ Flexible application by changeable blades R 0,5 – R 6,0

✔ Fast and easy change of the blades

✔ Holder for blades with hardened flattening part

Product Details

Jaminnar Wila blades holder's standard length are:

According to the length of the press brake machine worktable or the bent workpiece, it is used in combination.

PUNCHES/TOP TOOLS WITH SIMPLE CLAMP < 12,5 kg

500 mm

300 mm

200 mm

100 mm

550 mm sectionalized

✔ 10 Segments with horn extension left and right

✔ Sectionalized punches/top-tools are delivered as a complete set

✔ Upper punch: 100 (left horn) 25, 25, 30, 35, 40, 45, 50, 100, 100 (right horn) = 550mm (set)

2050 mm Tool Set

✔ 14 Segments, with Simple Clamp and horn extension left and right

✔ Sectionalized punches/top-tools are delivered as a complete set

✔ Upper punch: 100 (left horn) 25, 25, 30, 35, 40, 45, 50, 100, 200,300,500×2,100 (right horn) = 2050mm (set)

3050 mm Tool Set

✔16 Segments, with Simple Clamp and horn extension left and right

✔ Sectionalized punches/top-tools are delivered as a complete set

✔ Upper punch: 100 (left horn) 25, 25, 30, 35, 40, 45, 50, 100, 200,300,500×4,100 (right horn) = 3050mm (set)

4050 mm Tool Set

✔ 18 Segments, with Simple Clamp and horn extension left and right

✔ Sectionalized punches/top-tools are delivered as a complete set

✔ Upper punch: 100 (left horn) 25, 25, 30, 35, 40, 45, 50, 100, 200,300,500×6,100 (right horn) = 4050mm (set)

■ Create your own individual tool lengths set for punches/top tools and dies!

■ In addition to the above standard length and standard segment size, if you need to customize a special length or special segment length, please explain.

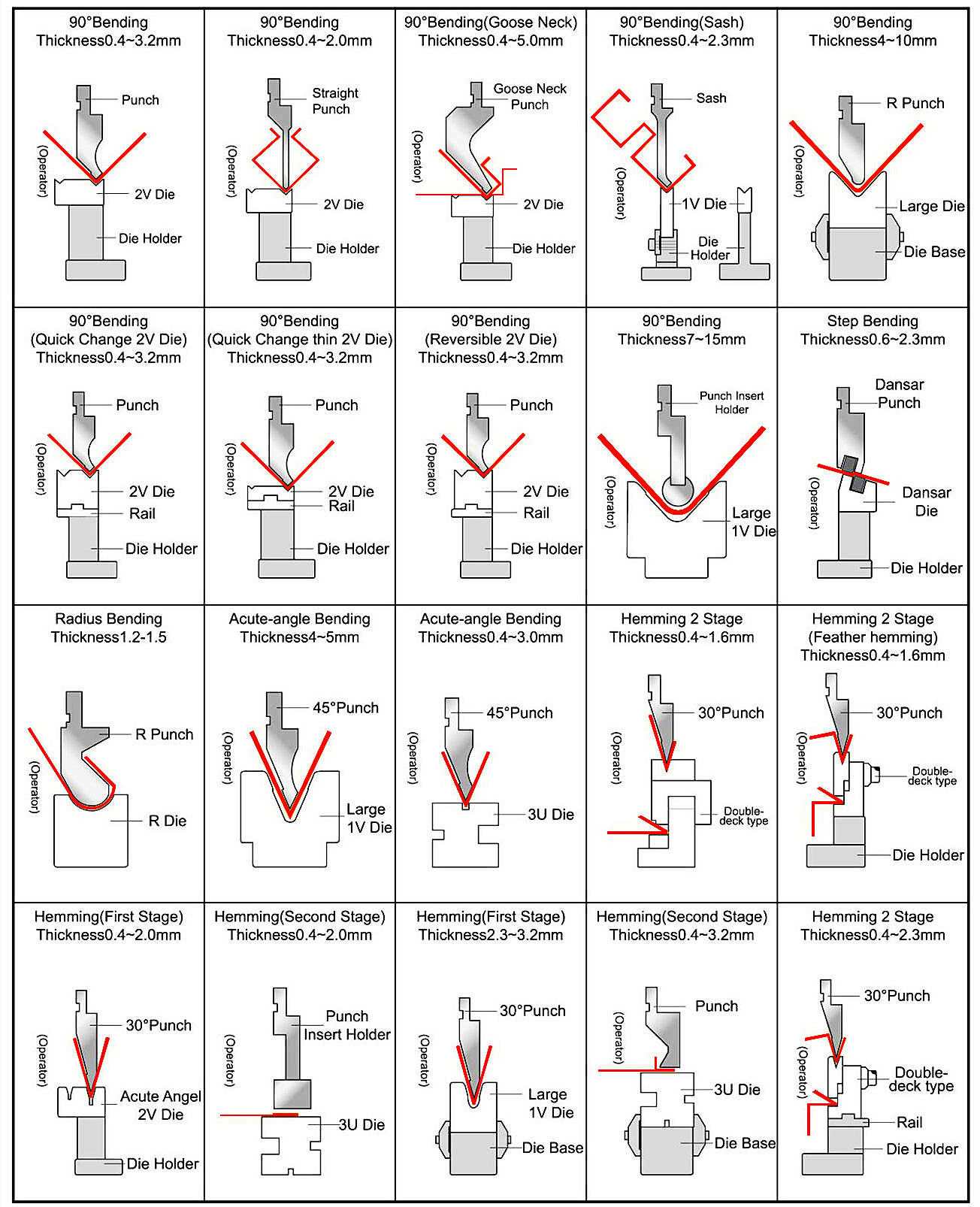

Bending Tools Combination Reference Table

Combination of Punches & Dies

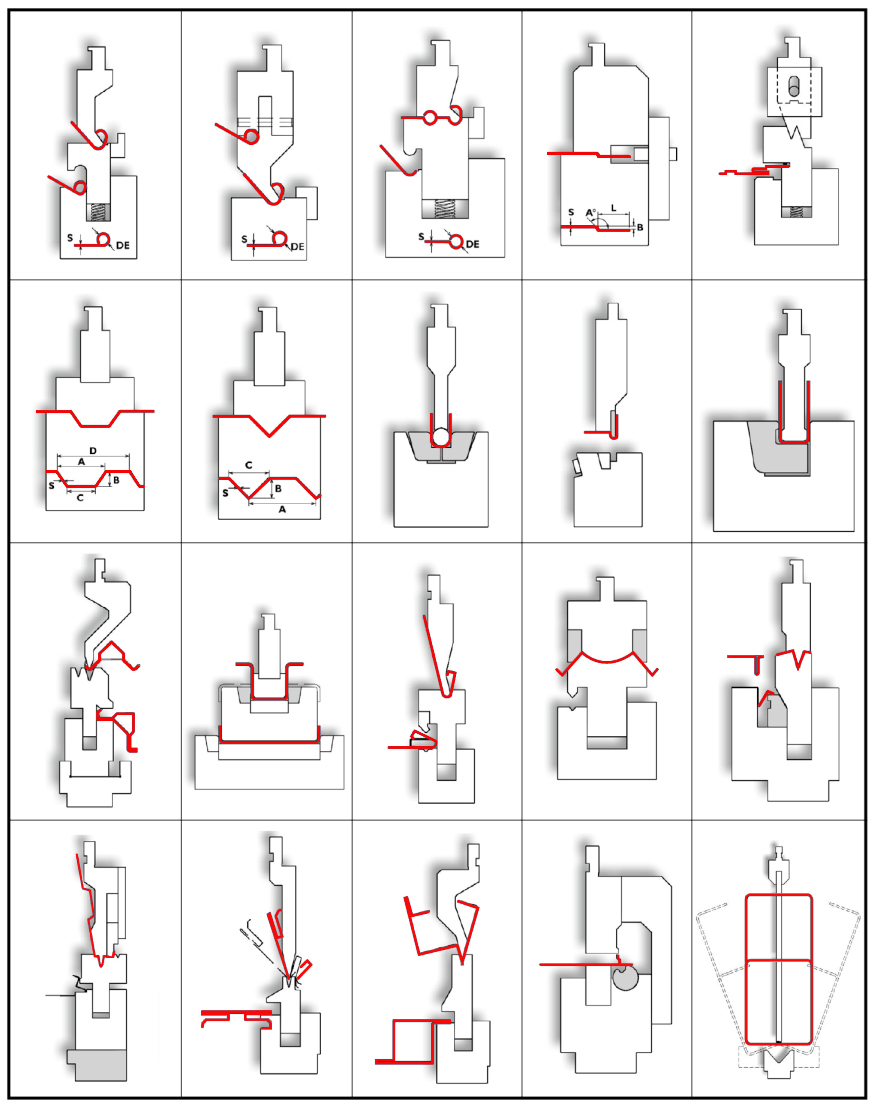

Forming Bending Tools Combination Reference Table

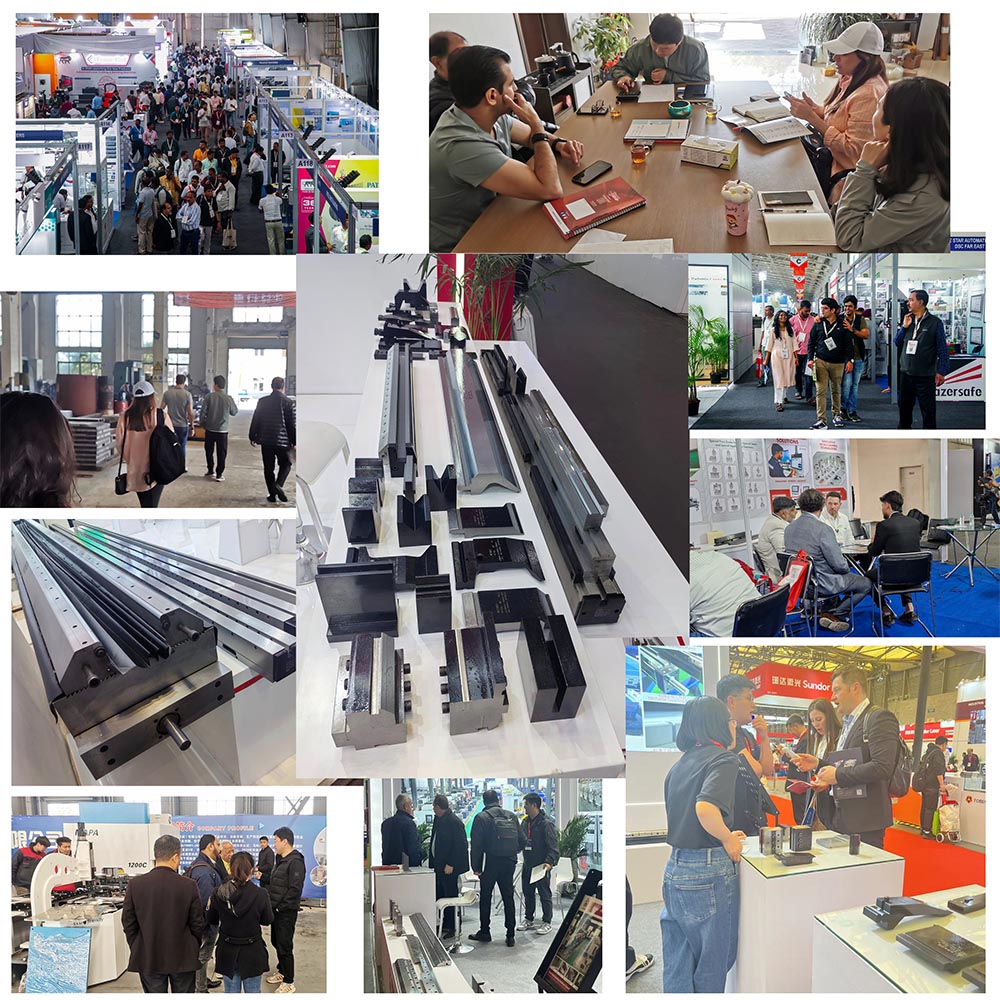

The company participates in trade shows, and customers visit the factory

for discussions and purchases.

Our Certificates

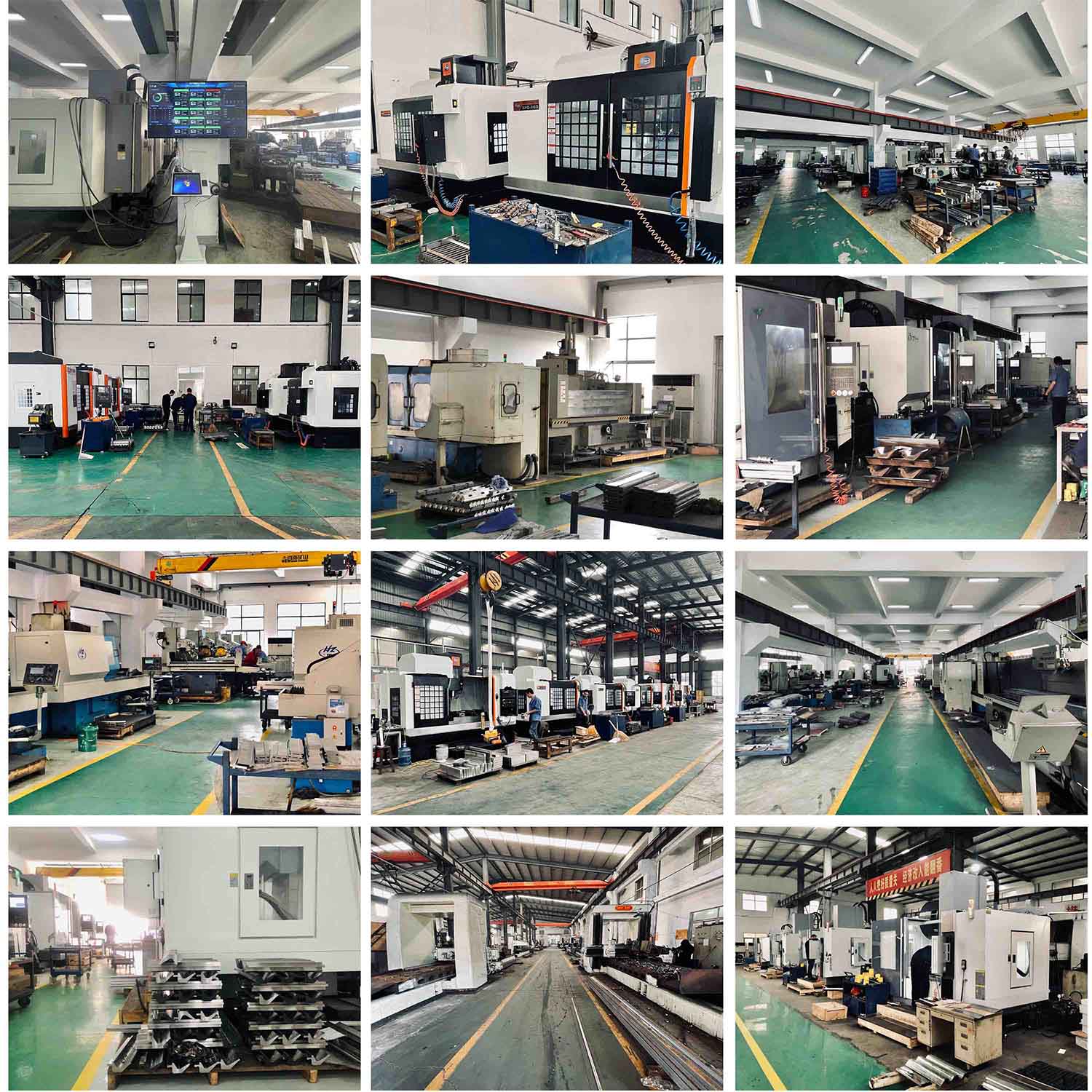

Our Factory

Shipping

FAQ

1. Q: Are you a factory or trading company? How is you factory production experience?

A: We are a factory. 24years Manufacturing experience. Leading supplier in Maanshan city.

2. Q: Can you put my brand logo on these products?

A: Yes, we can.

3. Q: What is the Minimum Order Quantity (MOQ) for your OEM service?

A: MOQ is 1pcs. Purchase amount not less than $50.

4. Q: When can you ship the products after we make payment?

A: Production time is normally 15-25 days.

5. Q: What materials and processing techniques are used for press brake tooling?

A: Material: 42CrMo4; Full body heat treatment HRC 44-50, CNC laser quenching HRC: 54-60; Surface treatment: silver, black coating or sandblasting

6. Q: How long is the warranty period for your products?

A: Under normal use, the warranty period is 1 year.

7. Q: What payment methods do you support?

A: T/T, Western Union, WeChat etc.