-

Give us a call

+86 17721551076 -

Email us

pressbraketooling@hotmail.com

Rotary Dies

Rotary dies are a great special tooling solution with numerous bending operation benefits. Because tonnage disperses with the movement of the rotating cam, the application requires less tonnage and makes bending sheet significantly easier for operators to handle. In some cases, using a rotary tool can cut labour costs in half, when more than one operator has traditionally been required, and improves safety. For cosmetic applications, rotary bending greatly decreases tonnage and part marking so sheets may require less protection and have improved finished appearance.

Rotary die features:

Improved safety for larger parts due to controlled material whip

Material marking is reduced since tonnage is reduced on the shoulder of the die and abrasion is lessened

Reduced tonnage on an application by 50% or more

Potential reduction in labor needs

Product Origin :

MaanshanBrand :

JaminnarOrder(MOQ) :

1Payment :

T/T, Western Union, Alipay, WeChat etc.Shipping Port :

Shanghai / Guangzhou or otherLead Time :

15 - 20 days after receiving the deposit|

JM - Custom rotary dies |

|

|

Tooling system |

JM - System Custom rotary dies |

|

Height |

Customizable Size |

|

Material |

42CrMo |

|

Length and weight |

Customizable Size |

Quality And Precision

▶Optimum materials

▶42 CrMo4, tempered to 1100- 1200 N/mm²

▶Bending Radius/Intake Radius Hardens to 54 – 60 HRC

▶Precision ground

▶Guaranteed exchangeability and parallelism

▶Tool marking with all technical information

Length: Customized according to customer requirements or according to the length of the workpiece.

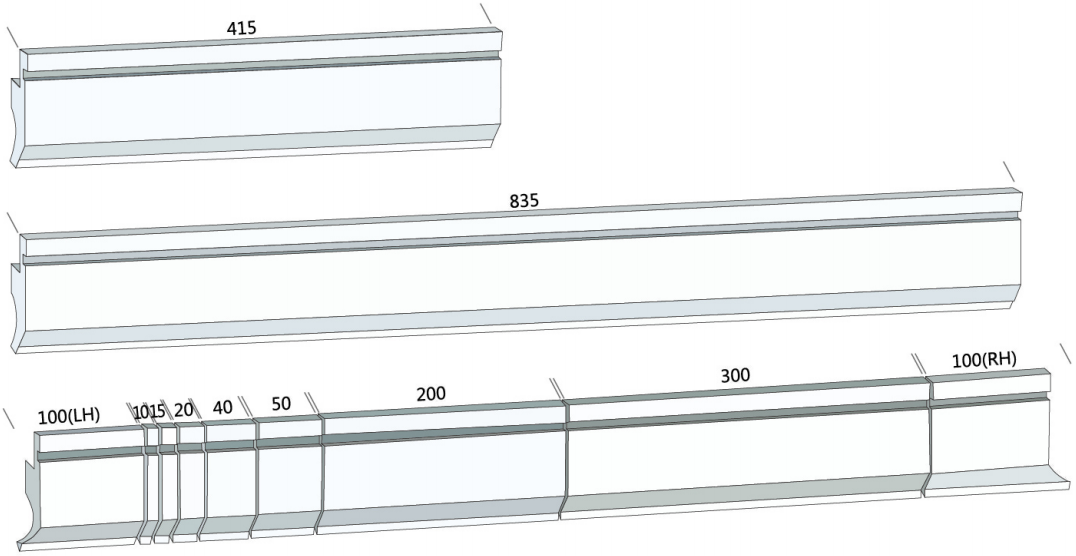

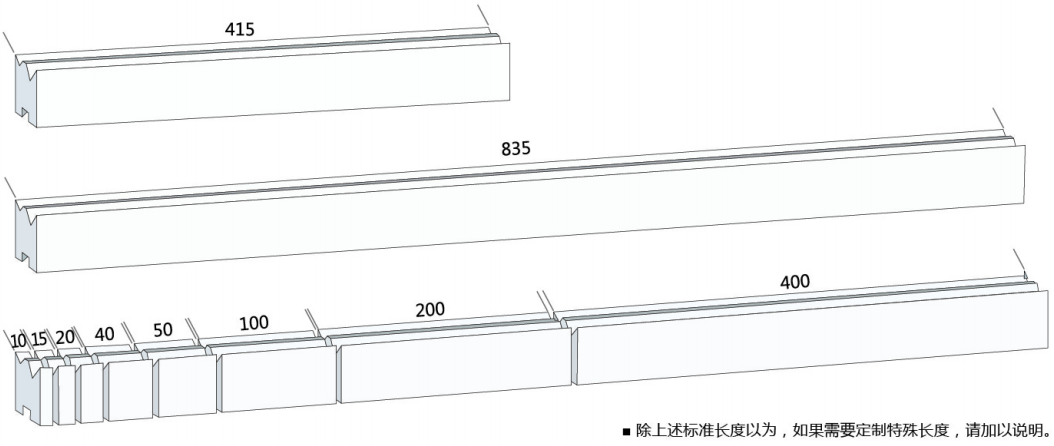

Jminnar press brake tooling's standard length is:

Two kinds of L835mm and S415mm. According to the length of the press brake machine worktable, it is used in combination.

The standard segmentation size is:

Upper punch 835 mm sectionalized

▶ 9 Segments with horn extension left and right

▶ Sectionalized punches/top-tools are delivered as a complete set

▶ Upper punch: 100 (left horn) 10, 15, 20, 40, 50, 200, 300, 100 (right horn) = 835mm (set)

■ In addition to the above standard length, if you need to customize a special length, please explain.

Lower die 835 mm sectionalized

▶ 10,15,20,40,50,100,200,400 = 835mm (set)

■ In addition to the above standard length, if you need to customize a special length, please explain.

FAQ

1. Q: Are you a factory or trading company? How is you factory production experience?

A: We are a factory. 24years Manufacturing experience. Leading supplier in Maanshan city.

2. Q: Can you put my brand logo on these products?

A: Yes, we can.

3. Q: What is the Minimum Order Quantity (MOQ) for your OEM service?

A: MOQ is 1pcs. Purchase amount not less than $50.

4. Q: When can you ship the products after we make payment?

A: Production time is normally 15-25 days.

5. Q: What materials and processing techniques are used for press brake tooling?

A: Material: 42CrMo4; Full body heat treatment HRC 44-50, CNC laser quenching HRC: 54-60; Surface treatment: silver, black coating or sandblasting

6. Q: How long is the warranty period for your products?

A: Under normal use, the warranty period is 1 year.

7. Q: What payment methods do you support?

A: T/T, Western Union, WeChat etc.