-

Give us a call

+86 17721551076 -

Email us

pressbraketooling@hotmail.com

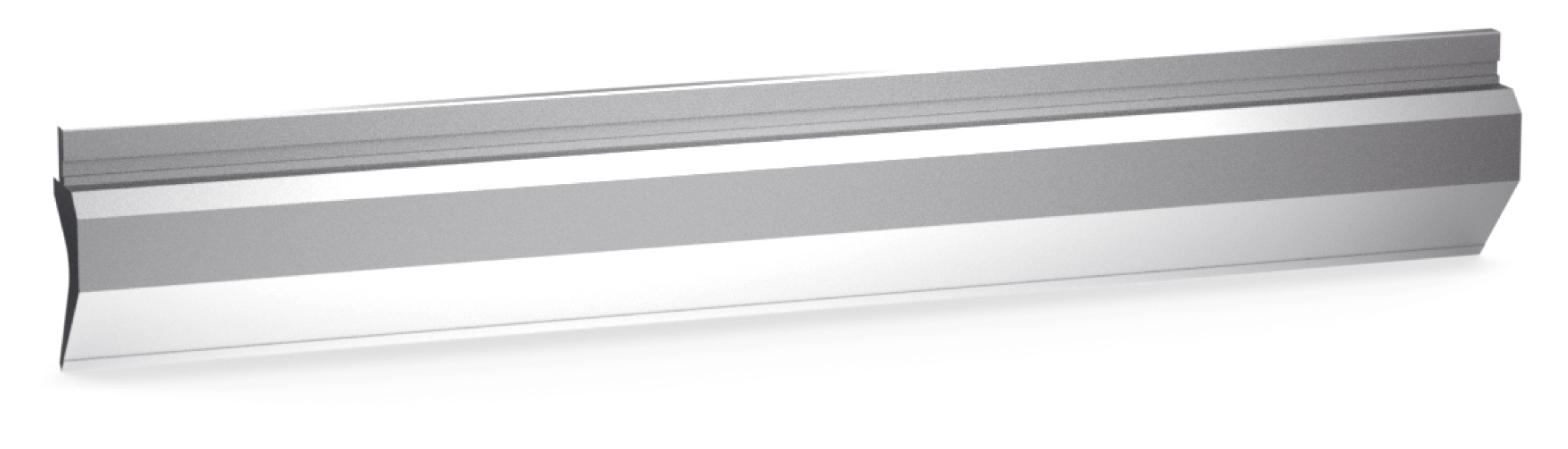

The gooseneck punch size: 215*95*835mm, 85degree. the material is 42CrMo4, hardness is HRC47+/-3, and height 215mm, width 95mm, the weight is 42kg. Can be made according to customer's request.

Tooling system :

JM-System AmadaArt.No. :

JM - 11850Brand :

JaminnarOrder(MOQ) :

1Payment :

T/T, Western Union, Alipay, WeChat etc.Product Origin :

MaanshanShipping Port :

Shanghai / Guangzhou or otherLead Time :

15 - 20 days after receiving the depositAngle :

85°Radius :

0.8mmMax load :

1000 kN/mMaterial :

42CrMo4Hardness :

HRC47±3 / HRC57±3Clamping System :

Amada/PromecamHeat Treatment :

Full body heat treatment / Laser hardeningLength and Weight :

835mm/42kg、415mm/21kgSurface Color & Surface Treatment :

Silver / Black / Sandblasting|

ART.NO.: JM - 11850 |

|

|

Tooling system |

JM - System Amada |

|

Angle |

85°、88°、90° |

|

Radius |

0.2mm、0.6mm、0.8 mm、1.5mm、3mm |

|

Effective Height |

185 mm |

|

Load |

1000 kN/m max. |

|

Material |

C45、42CrMo, 650 - 800 N/mm² |

|

Length and weight |

835mm/42kg、415mm/21kg |

Quality And Precision

▶Optimum materials

▶42CrMo4, tempered to 1100 - 1200 N/mm²

▶Bending Radius/Intake Radius Hardens to 54 – 60 HRC

▶Precision ground

▶Guaranteed exchangeability and parallelism

▶Tool marking with all technical information

835 mm

415 mm

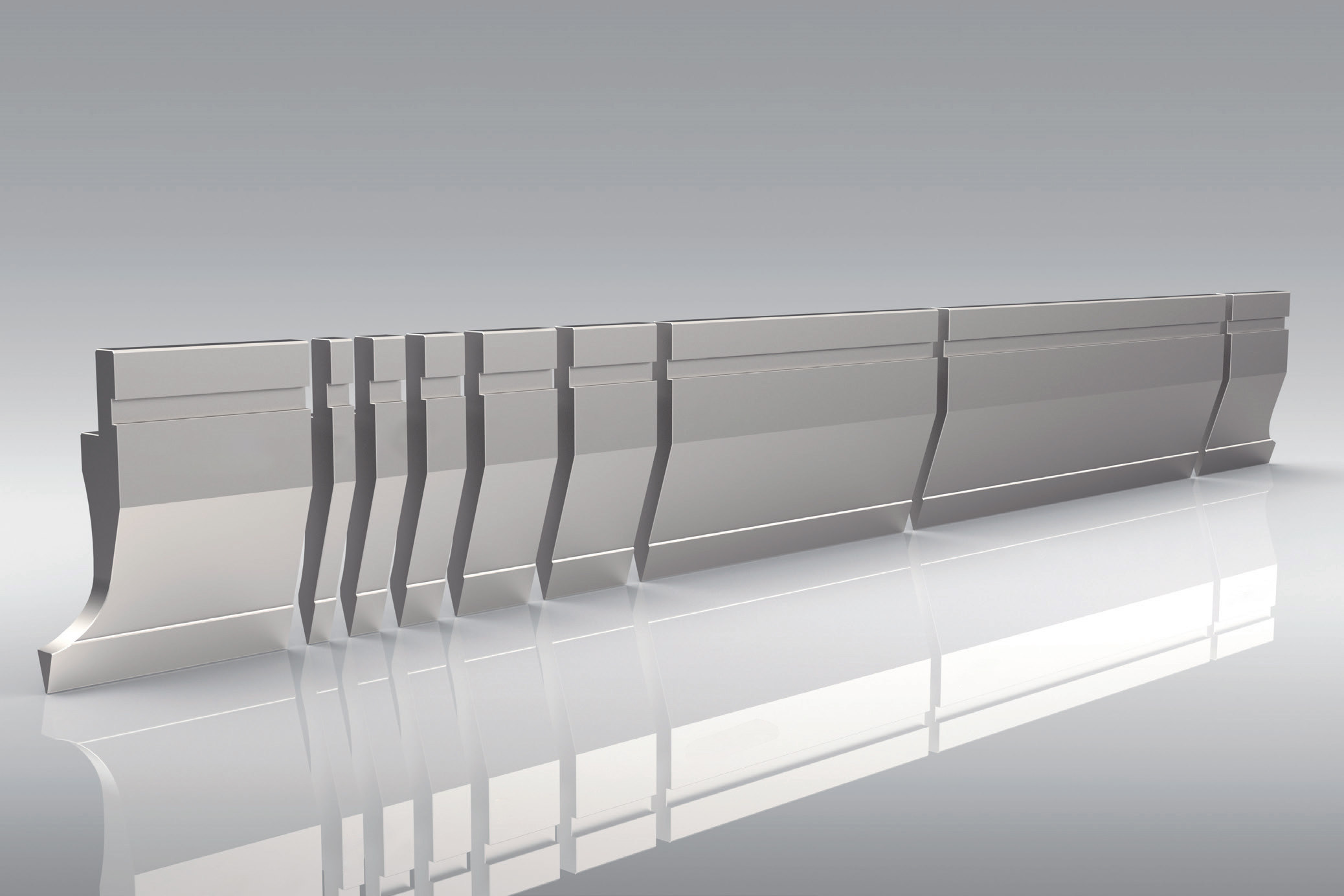

835 mm sectionalized

▶ 9 Segments with horn extension left and right

▶ Sectionalized punches/top-tools are delivered as a complete set

▶ Upper punch: 100 (left horn) 10, 15, 20, 40, 50, 200, 300, 100 (right horn) = 835mm (set)

■ In addition to the above standard length, if you need to customize a special length, please explain.

FAQ

1. Q: Are you a factory or trading company? How is you factory production experience?

A: We are a factory. 24years Manufacturing experience. Leading supplier in Maanshan city.

2. Q: Can you put my brand logo on these products?

A: Yes, we can.

3. Q: What is the Minimum Order Quantity (MOQ) for your OEM service?

A: MOQ is 1pcs. Purchase amount not less than $50.

4. Q: When can you ship the products after we make payment?

A: Production time is normally 15-25 days.

5. Q: What materials and processing techniques are used for press brake tooling?

A: Material: 42CrMo4; Full body heat treatment HRC 44-50, CNC laser quenching HRC: 54-60; Surface treatment: silver, black coating or sandblasting

6. Q: How long is the warranty period for your products?

A: Under normal use, the warranty period is 1 year.

7. Q: What payment methods do you support?

A: T/T, Western Union, WeChat etc.