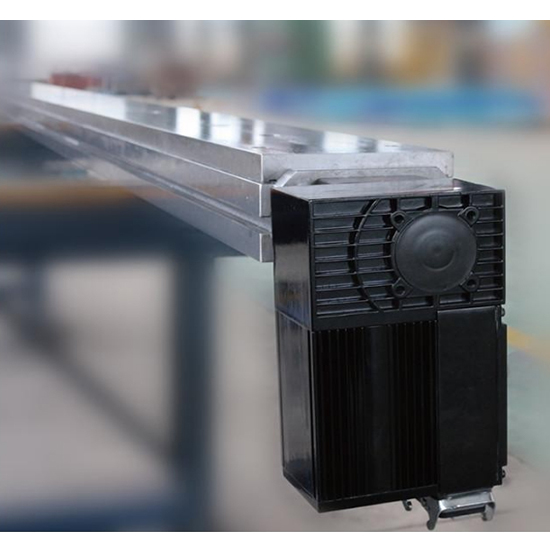

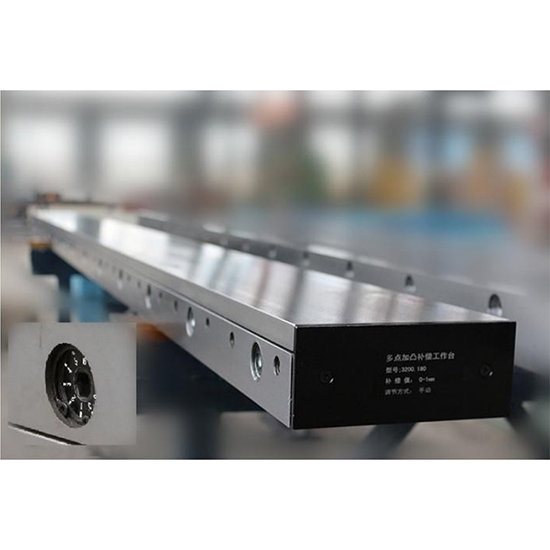

Amada Bending Thick Board Tool / metal bend tool

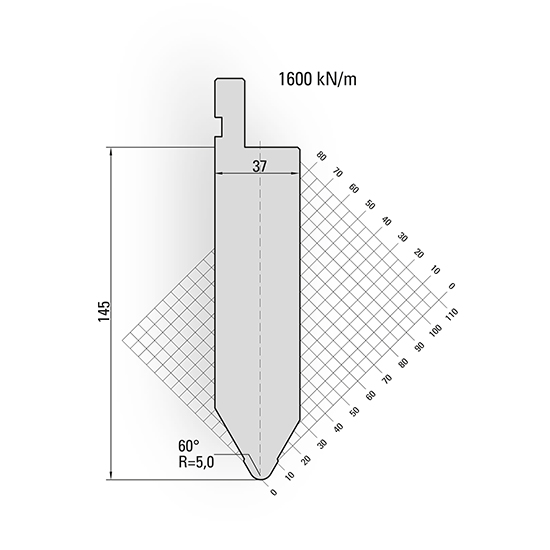

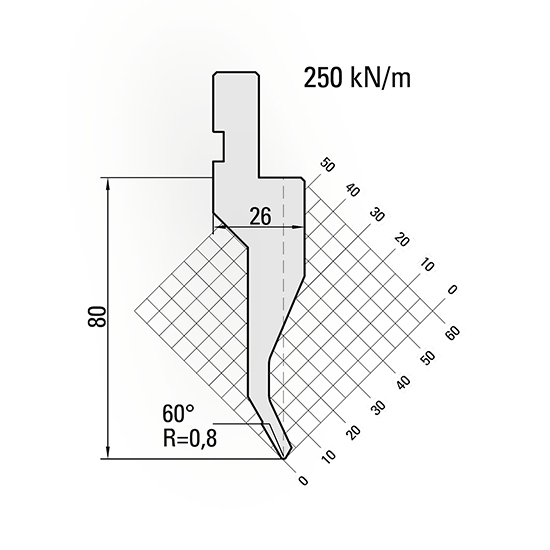

The straight blade size: 175*37*835mm, 60degree. the material is 42CrMo4, hardness is HRC47+/-3,the weight is 34.5kg.

We can make induction harden or all body heat treatment for customers.

For the segments size, we can make it according to the customer's requirements. if no request , we will make 835mm standard segments size for you,100L,10,15,20,40,50,200,300,100R.

Read More